ID3 Carbon Footprint

Monitoring of GHG Emissions with Indicators for the Most Efficient Use of Diesel Generators

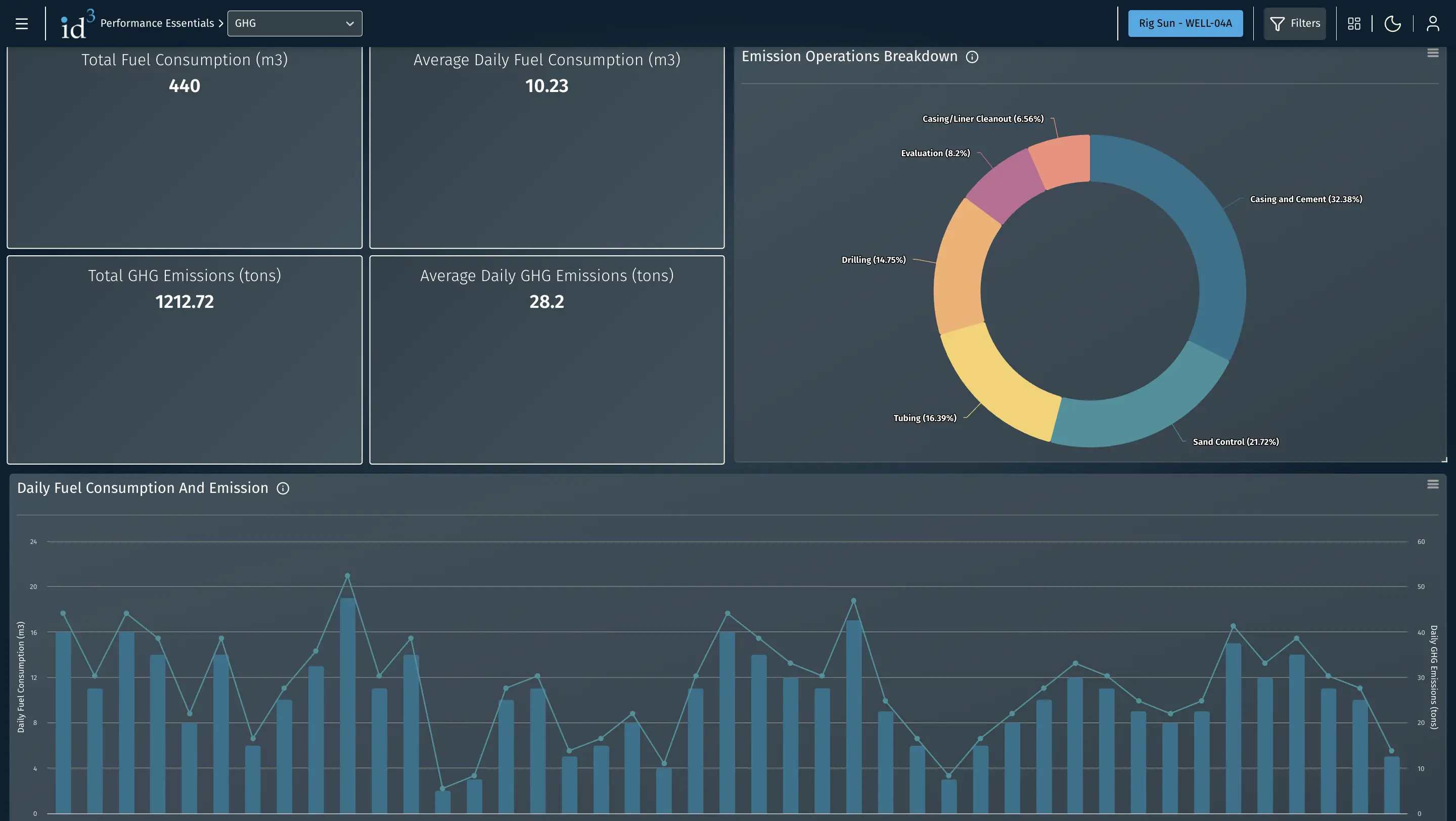

The ID3 Carbon Footprint module provides a comprehensive platform for analyzing and mitigating carbon emissions associated with drilling operational activities.

By leveraging advanced analytics and integration capabilities, this module enables users to gain deep insights into the carbon footprint of their drilling operations and implement targeted strategies for emission reduction.

Through seamless integration with a variety of data sources, including both low-frequency (LF) reporting systems and high-frequency (HF) engine data, the module offers a holistic view of carbon emissions across the entire drilling process. This integration allows for the collection and analysis of a wide range of relevant data points, such as fuel consumption, energy usage, equipment efficiency, and emission levels.

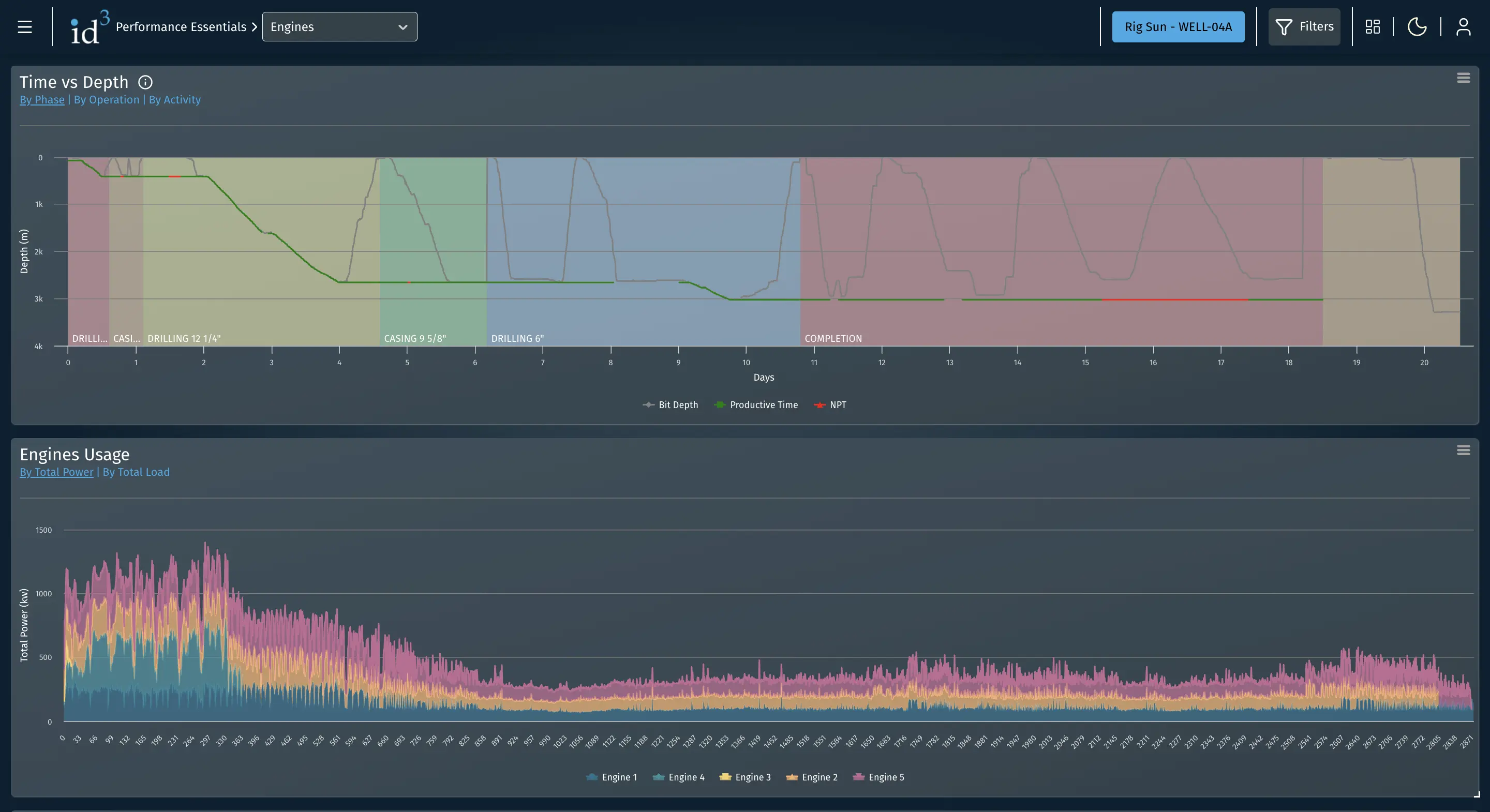

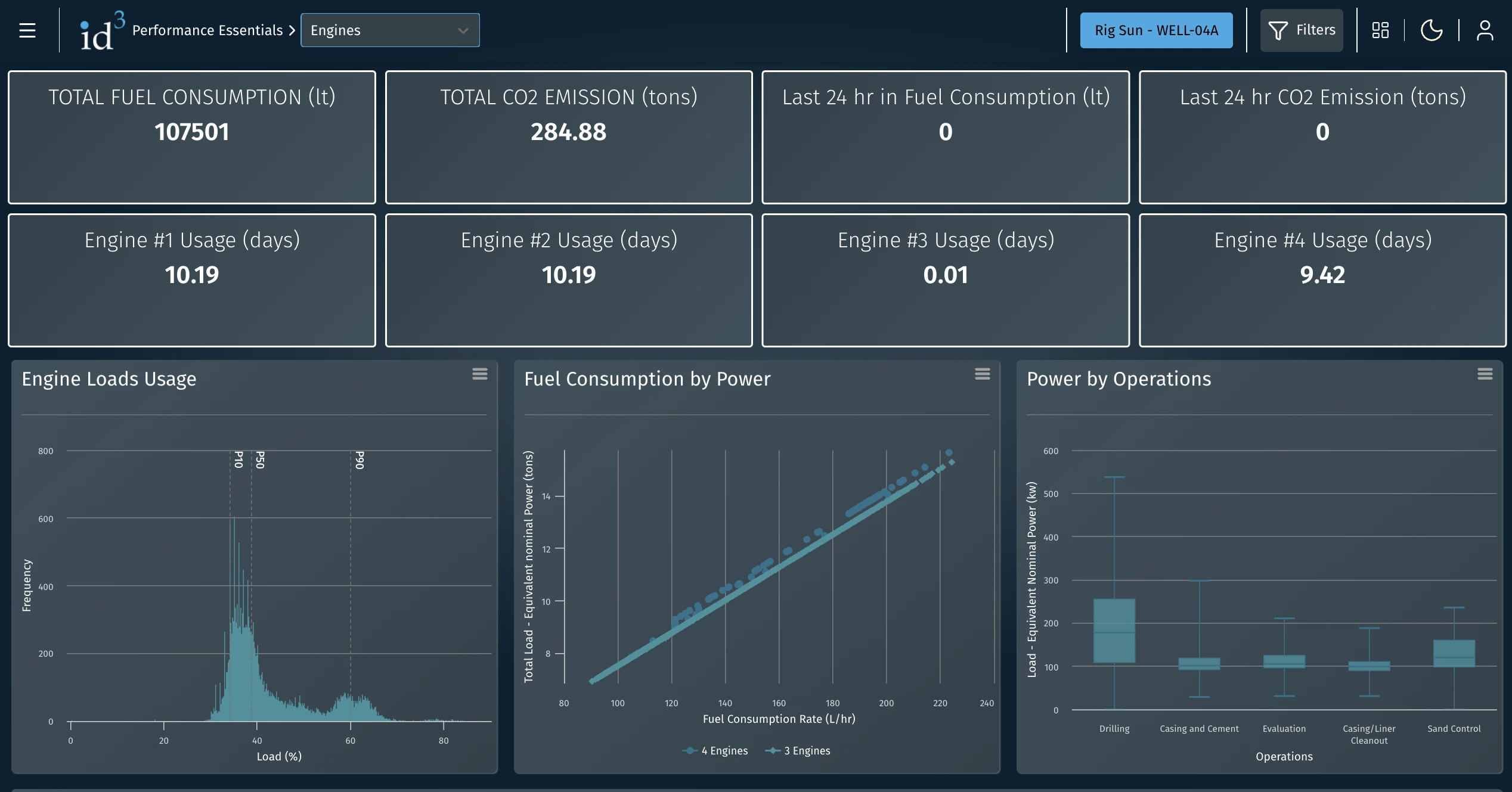

Our digitalization process collects real-time data from the rig site and headquarters, consolidating it seamlessly. Specialized algorithms continuously monitor the rig state every 5 seconds, while engine consumption data is sourced from reporting and monitoring systems. This data is presented on interactive dashboards, offering valuable information on fuel efficiency and energy consumption based on each rig’s operation type.

The system provides the best statistical performance achieved by the rig fleet as a benchmark for low-emission operations. Rig operators receive clear guidance on optimizing diesel generator use, ensuring operational safety and emissions reduction. Optimizing engine usage enhances availability by reducing failures and extends engine lifespan, contributing to improved maintainability.